JEWELRY DESIGN

Jewelry design

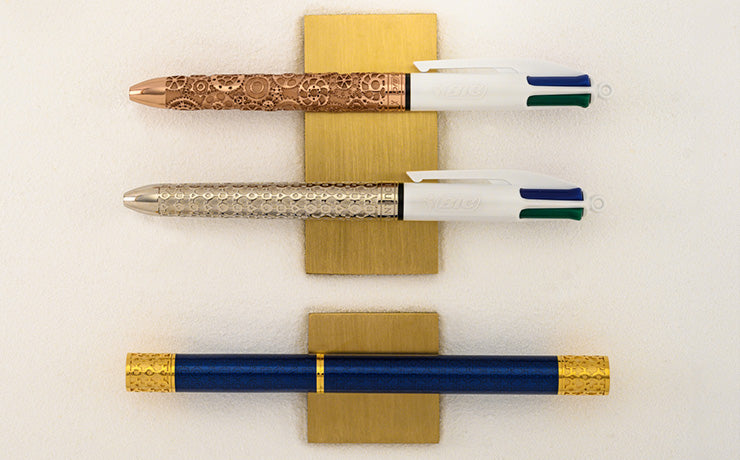

Discover all the secrets of jewelry design Tournaire. Tournaire uses classic jewelry-making techniquesJewellery and also develops many innovative techniques for the design of these jewels.

Design and waxes

Lost-wax casting is an age-old, highly precise technique. Most of the time, we use this process for our jewelry, because we can work the wax by sculpting, modeling or engraving it... This wax design stage is essential in the manufacturing process Tournaire.

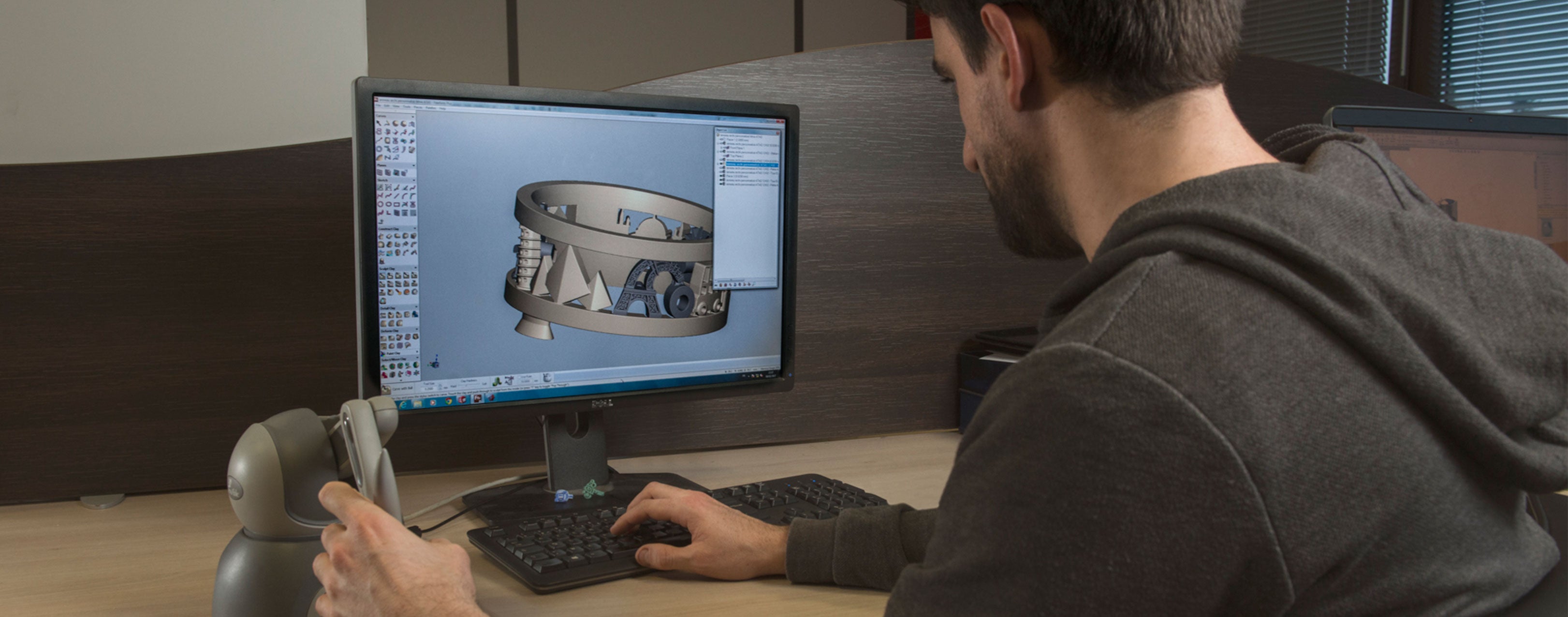

We also use another technique. In fact, we were one of the first jewelers to introduce 3-D design back in 1997, using a 4-axis 3D numerical control system. Ideas for the creation of a piece of jewelry are always born on paper, then translated into 3 dimensions on the computer. The representation of the jewel is then transmitted to a 3D printer which, by successive layers of wax, will create the matrix of the jewel.

We started out as UFOs in the Jewellery world, using 3D. Today, almost everyone uses it. In the beginning, people told us it wasn't Jewellery, but you have to move with the times: stone sculptors no longer use hammer and chisel. Even with the computer, it's the head that controls the hand that controls the mouse. If you give everyone a pen and paper, they won't write Victor Hugo. It's the same with 3D: without creativity and knowledge of technical constraints, we couldn't achieve anything.

We're fortunate to have a good knowledge of the workshop. It's not enough to know how to design beautiful jewelry, you also need to know the technical constraints involved in making it.

Other processes include forging, cutting, riveting or welding to produce a direct metal model, which can then be molded in rubber to produce replicas. The mold is cut in two to remove the model. All that remains is the imprint of the jewel. Wax can then be injected into the mold, enabling us to obtain wax models for casting. Various modifications can be made to waxes before casting. For example, a ring can be cut to fit the customer's finger.

This is a very delicate stage, as any defects remaining on the wax will show up on the metal, so you need to prepare your wax very carefully.

The waxes are mounted on a tree called a "wax tree". Once all the waxes have been installed, the shaft is ready to be "plastered". This step creates a cylindrical mold, the "casting cylinder", in refractory plaster, with the shape of the "wax tree " in negative, to accommodate the molten metals.

The precious metal is first heated to melting temperature and then converted to a liquid state. The cylinder with the"wax shaft"is heated beforehand to remove the wax and avoid thermal shock when the molten metal is poured. During casting, the liquid metal takes the form ofthe "wax shaft" in the casting cylinder. After cooling, the cylinder is broken open to releasethe "wax shaft",and the plaster is finally removed using a high-pressure water jet.

The guarantee of uncompromising craftsmanship

Our titles and labels

Made in France

Made in our workshop

100% secure payment

3x free of charge possible

Free delivery & returns

100% secure and free

Jewellery committed

Ethical and responsible jewelry