Setting stones

Setting stones

When a creative piece comes out of the casting process, the metal is in its raw state, meaning that its surface contains numerous imperfections that need to be corrected before the final result can be achieved. From abrasive discs to blowtorches for welding, the wide range of techniques and tools used at this stage can meet every need.

Preparation, adjustment, assembly and polishing

Every tiny part of the future jewel must be deburred, filed, emerized and polished to ensure a flawless finish. The rough metal is worked with abrasive tools, starting with a grosgrain to remove the rough appearance and even out the jewel's surfaces, followed by finer and finer grains with felt and cotton to give the jewel its shiny appearance. This step in the roughing process can take from a few hours to several days, depending on the difficulty of the assembly, preparation and complexity of the piece.

Choice of stones

I often start with a main stone, which the customer can bring or which I choose from my collection, and then I embellish it...

The choice of gemstones used for a piece of jewelry is not a trivial matter. Everything is meticulously selected to ensure that the harmony of shapes and colors is perfect and reflects the originality of each creation. Different types of stones are used during the manufacturing process. Gemstones and precious stones are set according to color.

Stone preparation is akin to the art of painting: stone types, shapes and colors are the painter's tools and palette. The challenge is to marry shapes and colors harmoniously.

But there are other factors to consider when choosing a stone, not least its cut. The shape of a gemstone is a feature that will influence its visual appearance, as its brilliance can vary, as can its cost.

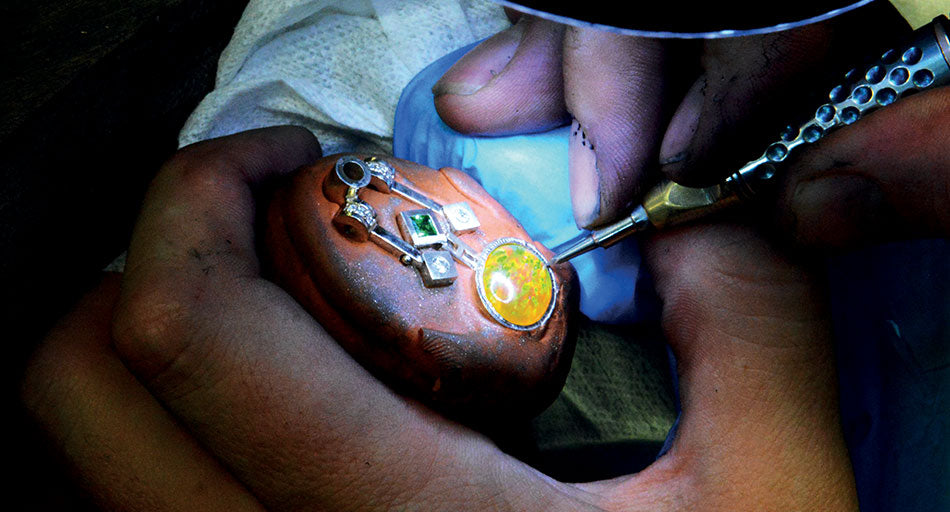

Crimping

One of the last stages of the work consists in attaching the stones to the jewel. This is a very meticulous stage, requiring great precision. There are several types of setting:

-Closed setting is the method we use most for reasons of comfort (because the stone is protected) and aesthetics, thanks to the mirror effect that seems to increase the size of the gem. The jewel is drilled and milled to the size of the stone it will house. The stone is then placed in it, and the metal around the stone is then folded over it using a hammering machine that acts like a miniature jackhammer. Next, the outline of the stone can be engraved from a scoop to obtain a shape, this is the "recutting" of the metal. The "flat" of the setting is then filed and polished, each movement executed with great precision to avoid damaging the stone.

This is why setters use binocular magnifying glasses, to be as precise as possible.

-Grain setting consists of pushing small metal grains onto the stone, holding it firmly in place.

-The rail setting involves setting the stones in a rail so that there are no gaps between them.

-The claw setting consists of holding the stone in place with claws, which the setter places on the stone.

Setting a ring can take from a few hours to several days, depending on the complexity of the design and the number of stones. This is the crucial step that can make or break a jewel.

The guarantee of uncompromising craftsmanship

Our titles and labels

Made in France

Made in our workshop

100% secure payment

3x free of charge possible

Free delivery & returns

100% secure and free

Jewellery committed

Ethical and responsible jewelry